The Three Musketeers, LanzaTech, Ensyn, Linde unveil SAF game-changer

At ABLC Next, news arrived that Ensyn, Linde Corp and LanzaTech have formed an alliance develop and implement the production of Sustainable Aviation Fuel other renewable fuels and a range of useful materials from cellulosic biomass including non-food plant material – primarily wood and wood residues.

Reminds us of the Three Musketerres — all for one, and one for all.

The Alliance

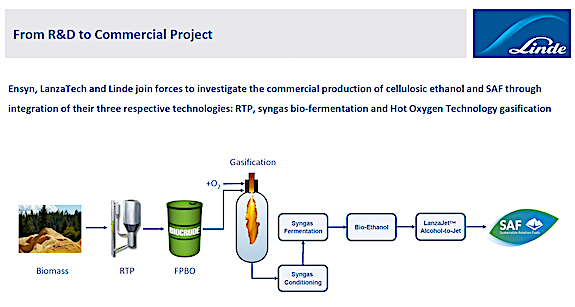

The alliance combines their three commercially-proven enabling technologies to take solid wood and produce SAF, renewable diesel, cellulosic ethanol and a spectrum of other consumer products.

The backstory

This all goes back to a DOE project with the three companies and academic partners that aimed at four deliverables. They were:

(1) showing that liquifying lignocellulosic biomass and sorted municipal solid waste by pyrolytic liquefaction enables it to be pumped and fed to a high-pressure gasifier

(2) demonstrating that conversion in an entrained- flow gasifier achieves more than 98% conversion of carbon to syngas

(3) proving that the syngas has negligible tar and soot and is suitable for fermentation to ethanol

(4) verifying that SAF production via entrained-flow gasification with syngas fermentation can achieve a fuel selling price cost-competitive with petroleum-based fuels, with greater than 50% conversion of biogenic carbon to fuel, and GHG reductions of at least 70% relative to petroleum-based equivalents.

The significance

Two themes stand out here to make this story huge for the bioeconomy. First of all, we are processing waste biomass and making jet fuel — so we have a pathway to immediately and vastly expand the feedstock set.

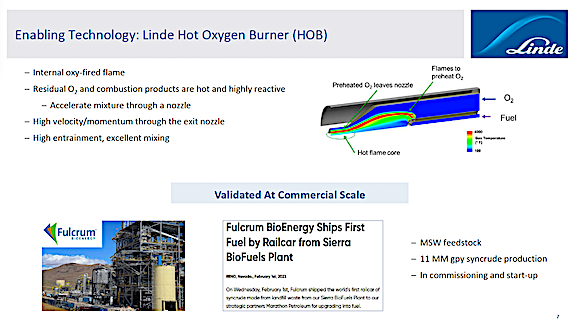

Now, you’re probably thinking “haven’t we had these feedstocks all along, haven’t we had technologies like Fulcrum to process the, all along? Well, yes and no. Feedstocks and technologies, yes; successful at scale, no. So, now we have, and the pathway is new — that is, liquefying the biomass, then gasifying. Thereby bypassing many of the problems that have beset biomass gasifiers — getting enough product of a consistent type pumped into eh reactor at a commercially viable rate. Sounds simple enough, no? Yet, it’s proven to be one of the toughest challenges in the bioeconomy, Now, perhaps, we have a workaround, boy did we need one.

Why? Because waste biomass of the types utilized here in this approach are of the $50-$80 per ton type envisioned in the DOE Billion Ton Study. Contrast that with the $1063 ton price of soybean oil this week to consider the potential impact on SAF prices. SO, think in terms of a $8500+ drop in SAF prices per ton, maybe more.

Bottom line, the world needs a cheaper source than plant oils (or waste oils, too) and hasn’t been a compelling alternative, financially, to date. Ethanol has not proven, yet, a compelling alternative. The key has been to unlock low-cost residues, and here’s a way.

Potential impact

The partners aver: Most steps in this strategy are commercial or have been demonstrated under industrially-relevant conditions. This project will demonstrate the technical feasibility of the least understood technological component – performance of bioliquids in the entrained flow gasifier. Broad deployment of a distributed, liquid format feedstock, coupled with entrained flow gasification, has the potential to produce 1 to 2.1 million barrels per day, or 71 to 152% of current aviation fuel demand, far exceeding the SAF Grand Challenge volumetric targets of 3 billion gallons per year by 2030 and 35 billion gallons per year by 2050.

The process story

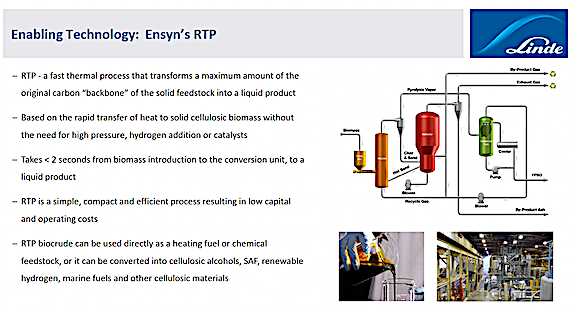

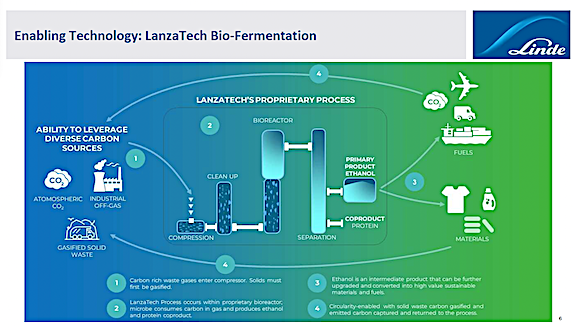

Ensyn’s RTP technology takes the carbon “backbone” of solid biomass materials and pushes the large majority of that carbon into a low-carbon liquid biocrude product. Linde then efficiently converts that liquid to a synthesis gas or “syngas” which is a standard building block for the production of valuable finished fuels and other products. Finally, LanzaTech converts syngas to cellulosic ethanol, which can be used directly as a final fuel product, or transformed into SAF, renewable diesel, and low-carbon consumer products. Combinations of the processes can also produce green hydrogen and marine fuels with efficacy.

Reaction from the stakeholders

Ensyn chairman Dr. Robert Graham noted, “We believe that this is a significant development in the mix of practical solutions, as modern economies quickly move towards the mitigation of climate change.”

More on the story

More on Linde here and LanzaTech here and Ensyn here.

Category: Top Stories