Back to Basics: Saving Power While Agitating Slurries in an Ethanol Plant

By Gregory T. Benz LEC Partners (formerly Lee Enterprises Consulting) and Benz Technology International, Inc.

Special to The Digest

A recent article in Ethanol Producer Magazine (1) highlighted the potential for growth in the ethanol industry, noting that Sustainable Aviation Fuel (SAF) can be produced from ethanol, which is predominantly made from corn in the USA. This promising development could lead to increased demand for corn-based ethanol, potentially necessitating the expansion or revamping of existing facilities. In light of this, it’s an opportune moment to revisit some fundamental principles on how to reduce agitator power requirements in an ethanol plant.

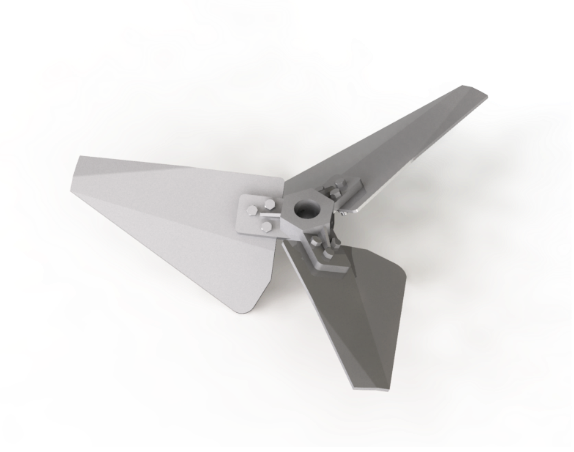

It’s widely acknowledged within the industry that the type of impeller used significantly influences power and torque requirements. In particular, narrow-blade hydrofoils (Figure 1) have emerged as a popular choice, requiring less than half the torque of pitched-blade turbines. In fact, the vast majority, probably 90% or more, of new ethanol facilities built in the last 30 years have adopted hydrofoil impellers in their slurry tanks. This widespread adoption instills confidence in the efficiency of these impellers, and as such, this article will focus on how to further enhance energy savings using hydrofoils.

Figure 1: Hydrofoil, courtesy Pro-Quip, Inc.

The main principle we will discuss here is the effect of the ratio of impeller-to-tank diameter (D/T) on power requirements. In general, small impellers operating at high speed require much more power than larger impellers operating at a slower speed to produce the same process result in flow-controlled applications, such as anaerobic fermenters, starch slurry tanks, and stillage tanks. This is because, at equal pumping capacity, the smaller impeller discharges its flow at a higher velocity, and the discharge head is proportional to velocity squared. Power equals flow times head, making it mathematically obvious that it will require more power from the smaller impeller. We can also think of this a bit intuitively from an example I discuss in my seminars: “Imagine trying to stir your coffee cup with a toothpick or even a stirring rod. I think you agree that you would expend more energy doing that than if you used a teaspoon, which moves much more liquid per stroke.”

Of course, there are limits to how large the impeller can be made. Obviously, a D/T ratio greater than 1 won’t work. More seriously, the largest D/T that should be used with a hydrofoil is about 0.5 in low-viscosity systems to avoid an undesirable flow pattern that can cause solids to settle in the middle of the tank. The smallest D/T ratio that is usually considered is about 0.2.

We will illustrate the possible power savings with an example table below, but first, we must establish how much agitation is needed.

An excellent way to quantify fluid agitation for flow-controlled applications was introduced by Chemineer in the 1970s (2). They described agitation with a 1 to 10 scale they called “ChemScale,” which is proportional to the characteristic fluid velocity in the tank. This approach has been expanded upon and updated for different impeller styles, especially for biofuels (3), by this author. Many years of experience and testing have indicated that the required minimum intensity of agitation to keep organic slurries such as starch, ground grain and stillage in suspension is about a ChemScale level of 3. That is what we will use for our illustrative example. (Note that only results are presented here, not calculation details.)

Our example consists of a 10m diameter tank containing 785m3, or 207,000 gallons, of slurry. To generate Table 1 below, we are using a specific gravity of 1.05 and a viscosity of 20 cP. The power draw is directly proportional to specific gravity, so the results can be easily adjusted for different slurry densities. The shaft speeds are chosen using standard AGMA (American Gear Manufacturers’ Association) speeds, though different agitator manufacturers may have slightly different available shaft speeds.

| AGMA shaft speed, rpm | Impeller diameter, m | D/T | Shaft power, kW |

| 84 | 2.12 | 0.21 | 37 |

| 68 | 2.27 | 0.23 | 27.6 |

| 56 | 2.42 | 0.24 | 21.3 |

| 45 | 2.6 | 0.26 | 15.8 |

| 37 | 2.77 | 0.28 | 12.1 |

| 30 | 3 | 0.30 | 9.6 |

| 25 | 3.17 | 0.32 | 7.3 |

| 20 | 3.4 | 0.34 | 5.3 |

| 16.5 | 3.65 | 0.37 | 4.2 |

| 13.5 | 3.9 | 0.39 | 3.2 |

| 11 | 4.15 | 0.42 | 2.4 |

| 9 | 4.45 | 0.45 | 1.9 |

| 7.5 | 4.75 | 0.48 | 1.5 |

Table 1 Equivalent impeller size and shaft speed combinations

This table clearly illustrates the huge energy savings that can be achieved by using larger impellers at slower shaft speeds. Most ethanol plants operating today have a D/T ratio between 0.3 and 0.4. New installations therefore could benefit from a change in design to a larger D/T ratio. Depending on power cost, it may even be economically feasible to replace existing agitators with new ones with a larger D/T ratio, or possibly change the gear ratio or motor speed to operate at a lower shaft speed with larger retrofitted impellers. This author thinks it is worth looking into.

About the Author

Greg is a registered Professional Engineer with over 40 years of experience in the design of agitation systems. He specializes in fermentation and bioreactors, including heat transfer and mass transfer. He is the author of “Agitator Design for Gas-Liquid Fermentor and Bioreactors” and “Agitator Design Technology for Biofuels and Renewable Chemicals,” and is well known to most of the biofuel and biotechnology providers. He also has experience in continuous flow and multistage reactor design. Greg’s work involves agitation, mixing, and bioreactor design consultation, including equipment specification and bid evaluation. He has designed more than 150 fermenter agitators, as well as many polymer and biofuel agitation systems, including bioethanol, biobutanol, cellulosic ethanol, and biodiesel, as well as value-added renewable chemicals and biochemicals. He is a member of AIChE, ISPE, SIMB, SBE, American Mensa, and the American Chamber of Commerce in Shanghai. Greg has authored more than 35 technical articles and has specific experience doing business in China, having managed his former employer’s business there for years and having consulted there for multiple clients.

About LEC Partners (formerly Lee Enterprises Consulting)

LEC Partners has over 180 experts to help you navigate your bioeconomy needs. If you need assistance with your bioeconomy-related project(s), please get in touch with us at www.lee-enterprises.com.

References

1) D. Collings, “Alcohol to Jet: A Lifeline for Corn Ethanol”, Ethanol Producer Magazine, July, 2024, pp 36-40

2) R. Hicks, J. Morton, J. Fenic, “How to design agitators for desired process response”, Chemical Engineering Magazine, April 26, 1976, pp22-30

3) Book, G.Benz, “Agitator Design Technology for Biofuels and Renewable Chemicals”, published by John Wiley and Sons, 2022

Category: Top Stories