Cost-effective renewable fuel production with feedstock flexibility and minimized emissions has arrived

The urgency of climate change mitigation and the need to meet the global obligation for a net-zero world have made it imperative to explore every way possible to cut greenhouse gas (GHG) emissions. One of the ways is to change how we produce energy, with a focus on decarbonization across heavy industries, the transport sector, and related infrastructure.

Renewable fuels will play a key role in decarbonization and the future of the energy industry. But how can renewable fuels be optimized so that production emissions are minimized, changing regulatory requirements are met and business cases are future-proofed? Milica Folić and Adam Kadhim, Product Line Directors at Topsoe, take a look.

Removing the obstacles

Incentivization and regulation are two significant factors driving the growth in renewable fuel production globally. For instance, the Renewable Energy Directive (RED) in Europe, the Inflation Reduction Act (IRA) in the US and Clean Fuel Regulations in Canada, are just three legislative pillars encouraging fuel producers to step up renewables production, whether though greenfield plants, diversification projects or revamps to existing operations.

As the industry continues to derisk and standardization gains traction, the business benefits are becoming clearer. Three of the primary challenges facing renewable fuel producers can be boiled down to cost effectiveness, the flexibility to process diverse renewable feedstocks that vary in quality and type, and the significant consumption of hydrogen, which traditionally relies on fossil feedstocks like natural gas. Key in meeting these three factors head on are high-performing and proven technology and the ability to remain flexible when it comes to feedstock.

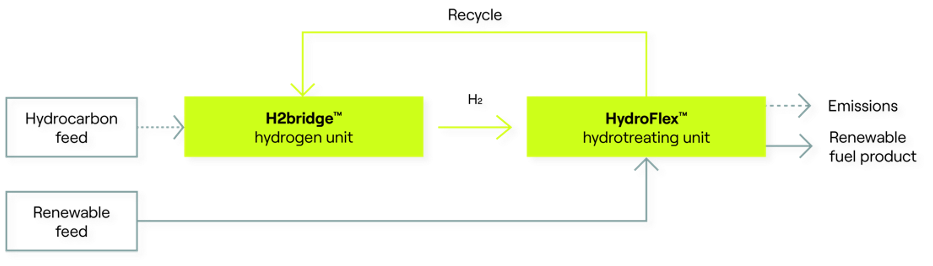

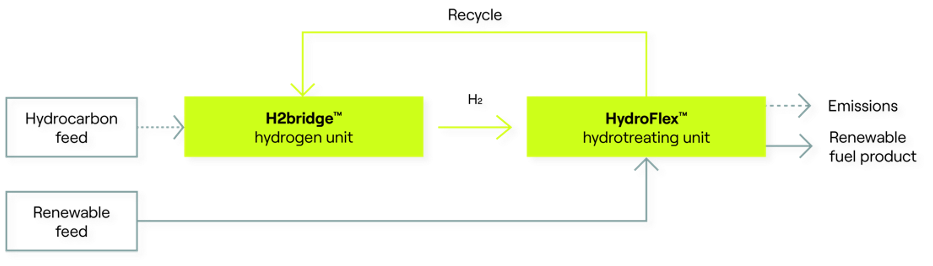

With these customer priorities in mind, Topsoe has focused on developing solutions that allow refineries and renewable fuel producers in general to future-proof their operations, enabling the production of renewable fuels with low emissions from a wide variety of feedstock. But the answer to providing a single optimized outcome for the sustainable production of renewable fuels is not one technology alone, but rather comes in the form of the combined capabilities of the HydroFlex™ hydrotreating unit and the H2Bridge™ hydrogen unit.

These two technologies allow renewable fuel production with low emissions from a variety of feedstocks. By integrating H2Bridge with HydroFlex, refineries can create a self-sustaining, low-carbon solution that can meet evolving specifications and legislative requirements.

HydroFlex: The hydrotreating technology

HydroFlex is a technology that allows for the hydro-treating of various renewable feedstocks to produce fuels like diesel, jet fuel, and naphtha. The technology is designed to be flexible and can be implemented in both new and existing refinery units so a wide range of feedstocks can be processed – and alongside fossil fuels if required. To meet specific and unique requirements, tailored units are designed, and proprietary catalysts for renewable fuel production are selected to ensure high-grade renewable fuels and diesel. Not only do these fuels meet international standards, but they are also fully compatible with modern combustion and jet engines and can be blended safely with traditional fuels.

Every refinery is unique, and so are the renewable feedstocks they process. HydroFlex units are designed to fit the specific needs of each refinery, considering factors such as size, location, and target product slate. This flexibility ensures that the resulting fuels always meet the specified quality, regardless of the varying quality and type of feedstocks.

Since its development in 2004, HydroFlex technology has been continuously refined and is now used in many refineries worldwide, with over 50 sold licenses. The technology’s adaptability and proven track record make it a reliable choice for producing renewable fuels that meet the highest standards. It also offers flexibility for feedstocks, so if availability or legislation demand a feedstock change, HydroFlex can still deliver.

Introducing circularity with H2bridge

Processing renewable feedstocks is not as straightforward as processing non-renewables, primarily due to the extra hydrogen needed. Hydrogen plays a crucial role in hydrotreating renewable feedstocks, which contain oxygen and unsaturated compounds. The consumption of hydrogen in this process is significant, and traditionally, this hydrogen has been produced from fossil feedstocks like natural gas. However, depending on the plant’s requirements, it is possible for producers to become self-sufficient and eliminate the consumption of external natural gas.

What is required to achieve this is a solution that allows for the replacement of these external fossil feedstocks. This is where H2bridge comes in as it enables refineries and biorefineries a circular solution that integrates seamlessly with HydroFlex. It enables the production of hydrogen from renewable LPG or naphtha by recycling off-gases from the hydrotreating process. By producing hydrogen from renewable sources, H2Bridge helps refineries lower their carbon footprint and achieve substantial GHG savings. The integration creates a self-sustaining system with better heat integration that can significantly lower both capital expenditure (CAPEX) and operational expenditure (OPEX), while it also reduces water usage compared to traditional hydrogen production from natural gas.

The combined advantage

The concept for combining a solution like H2bridge with HydroFlex developed after an exploration of how carbon emissions could be reduced in processing renewable feedstocks. This is where hydrogen’s role in emissions became apparent and led to further calculations and knowledge gathering about the needs in the market. This allowed a speeding up of the process that led to the development of a unified offering that presents large OPEX and CAPEX savings and minimized carbon emissions. With HydroFlex and H2bridge, hydrogen is no longer just a utility – it’s a profit maker.

The integration of HydroFlex and H2bridge was designed for the production of renewable fuels in a fully self-sustaining solution – feed-in to product-out process. This results in low carbon intensity fuels. These solutions are adaptable for both revamps and grassroot plants, enabling the conversion of a wide variety of feedstocks, including low-value feedstocks, into renewable fuels that meet changing specifications and legislative requirements.

There are other clear commercial advantages for the industry. Often, due to legislation, the more emissions are reduced, the higher the value of the product. Meanwhile, OPEX costs can be reduced with H2bridge due to no import of natural gas, better heat integration and a more efficient use of water.

Catalysts at the core

The performance of any renewable fuel process is heavily dependent on the efficiency of catalysts. Processing renewable feedstocks involves more complex contaminants than processing fossil feedstocks, leading to different chemical reactions. Since contamination is irreversible, it’s especially important to have the right guard catalysts to avoid irreversibly contaminating the bulk catalyst and potential pressure drop build-up, resulting in more downtime and less yield.

HydroFlex combines leading-edge unit design with a comprehensive range of high-performance proprietary catalysts tailored to the specific demands of each refinery. These catalysts ensure great yield, on-spec quality, and optimal performance, even when processing feedstocks with severe contaminants. As a result, Topsoe maintains a strong selection of catalysts and continually develops new ones to meet the evolving needs of the industry, ensuring that refineries can always achieve the best results from their feedstocks.

Conclusion

Hydrogen units are no longer just utilities; they are now integral to reducing emissions and increasing profitability.

The future of renewable fuels lies in technologies that offer flexibility, efficiency, and sustainability. H2Bridge and HydroFlex represent a significant step towards this future by providing refineries with the tools they need to produce low-carbon, high-quality renewable fuels. As the demand for sustainable energy solutions grows, these technologies will play a crucial role in achieving global decarbonization goals through renewables.

By integrating these technologies, refineries can not only meet current and future legislative requirements but also gain a competitive edge in the market. The shift towards renewable fuels is both necessary and inevitable, and with H2Bridge and HydroFlex, refineries are well-equipped to lead the way towards a net-zero world.

<ends>

Category: Thought Leadership, Top Stories