Elevating the EU’s Sustainable Energy Landscape: A Focus on Low-Carbon Ethanol and Innovative Solutions

By Mr. Amol Sheth, Assistant Vice President – Business Development, Advanced Biofuels and Chemicals (Global Market), Praj Industries

Special to The Digest

The European Union is leading the way in sustainable energy solutions through structured policy initiatives to achieve its Net Zero goals by 2050 under the ambitious European Green Deal. The Net-Zero Industry Act, a key component of the Green Deal Industrial Plan, streamlines regulations to attract investments in essential products, enhancing the competitiveness of the net-zero technology sector. Simultaneously, the revised Renewables Energy Directive (REDIII) sets a higher target of 42.5% for renewable energy in the EU’s overall consumption by 2030. Amidst intensified efforts to combat climate change, the transportation sector remains a major contributor to greenhouse gas emissions. Meeting the imperative for low-carbon ethanol becomes crucial, offering a cleaner fuel alternative derived from renewables, aligning with emission reduction targets and broader initiatives for innovation, energy security, rural development, and a sustainable EU energy landscape. The shift away from natural gas in ethanol production is imperative for sustainable practices in achieving the EU’s decarbonization goals.

At Praj Industries’ we have demonstrated solutions that will help to adopt flexibility with transformative change to make businesses profitable by reducing up to 90% of natural gas consumption and achieving electrification of ethanol plants. We have successfully integrated and implemented Mechanical Vapour Recompression (MVR) technology making businesses profitable in this competitive market.

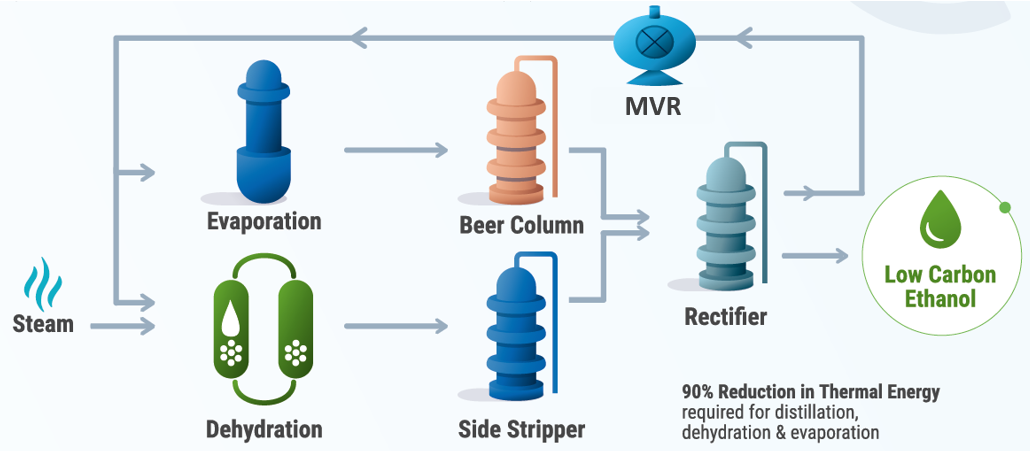

The energy consumption of 1G ethanol plants can be optimized by techno-commercially viable heat integration solutions at different sections. Praj’s MVR technology intensively utilizes the waste heat and steam from the plant and efficiently converts it into energy that is reused.

Alcohol MVR technology

The production of ethanol requires numerous energy-intensive processes including distillation, dehydration, evaporation, cooking, and drying. New technologies like networked alcohol vapor compression, in addition to methods like heat integration via cascading heat exchanger networks, significantly lower thermal energy requirements.

Recompressing process vapours with a heat pump, often referred to as mechanical vapour recompression, allows for the return of waste heat from the distillation/dehydration and evaporation stages. This process of energy integration through Alcohol MVR reduces the need for thermal energy for the operations by more than 90%.

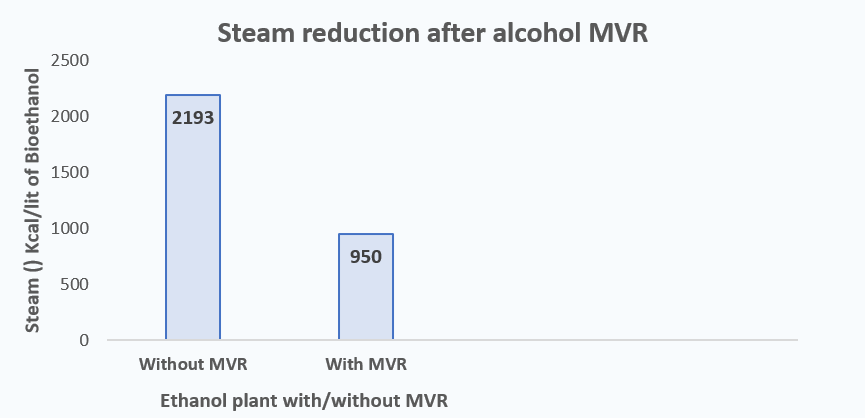

A typical grain-based 1G ethanol plant in Europe uses ~2193 Kcal of energy/lit of Bioethanol for its operations. Reduction of energy depends upon plant configuration and the possibility of integrations. Normally corn-based plants reduce 600 to 720 Kcal/lit of thermal energy after the installation of alcohol MVR technology (up to 900 Kcal in the case of other feedstocks like wheat where alcohol concentration in beer is lower). This will reduce the energy use by an equivalent number. There will be an additional requirement of 0.15 to 0.22 kWh/lit for the compressors.

Following graph shows the reduction in steam after alcohol MVR installation.

The following technologies further reduce the natural gas consumption:

- Methane production through stillage Bio-methanation.Methane will replace the existing natural gas for steam generation or direct dryers.

- Recovery of energy from dryer vapors integration with existing DDE (Distillation Dehydration Evaporation).

Reducing natural gas consumption will help boost the production of low-carbon ethanol while de-risking businesses from external geopolitical volatility in the fuel supply market.

Benefits to producers

While implementing this solution, as a technology provider our approach is to make it techno-commercially viable helping ethanol producers to achieve maximum value from the environment and economy.

- Ensure efficient asset sweating with the use of existing plant setup with quick turnaround time

- Plug & play quick implementation without affecting the production cycle within 7 to 8 months.

- Up to 90% reduction in natural gas consumption through electrification of existing operations

- 60 to 80% reduction in cooling water consumption.

- 35 to 45 % reduction in Greenhouse gas

Conclusion

In conclusion, the European Union’s commitment to sustainable energy solutions, exemplified by initiatives like the Net-Zero Industry Act and REDIII, reflects its dedication to achieving ambitious Net Zero goals by 2050. As the transportation sector poses challenges to emission reduction, the imperative for low-carbon ethanol stands out as a crucial solution, aligning with broader sustainability objectives. At Praj Industries, we contribute to this transformative journey by offering solutions that significantly reduce natural gas consumption and enable the electrification of ethanol plants. Our proven Mechanical Vapour Recompression (MVR) technology optimizes energy consumption in ethanol plants, showcasing a techno-commercially viable approach to sustainable and profitable operations in the competitive market. Through innovative heat integration solutions, Praj maximizes the utilization of waste heat and steam, contributing to a more sustainable and efficient energy landscape.

Category: Thought Leadership, Top Stories